Leverage Type Suppliers and Materials

We recently had a person in a class ask us to give examples of a “Leverage” type of materials to understand what kind of procurement approach to use. We’ll use this explanation of classifying suppliers and materials to cover Leverage and others too.

When deciding which suppliers to seek out, we must start with clarity about our strategy for our business. Are we a high volume, low margin producer of baked sandwich bread shipping into a large distribution network, or are we a mom and pop custom bakery on the corner with high quality, low volume demands? This informs the procurement focus based on what the market has to offer, our planned volume, how complex our needs are and the costs of various approaches. This further directs our supply chain decisions to support our value proposition. We begin by classifying materials and suppliers into 4 main categories.

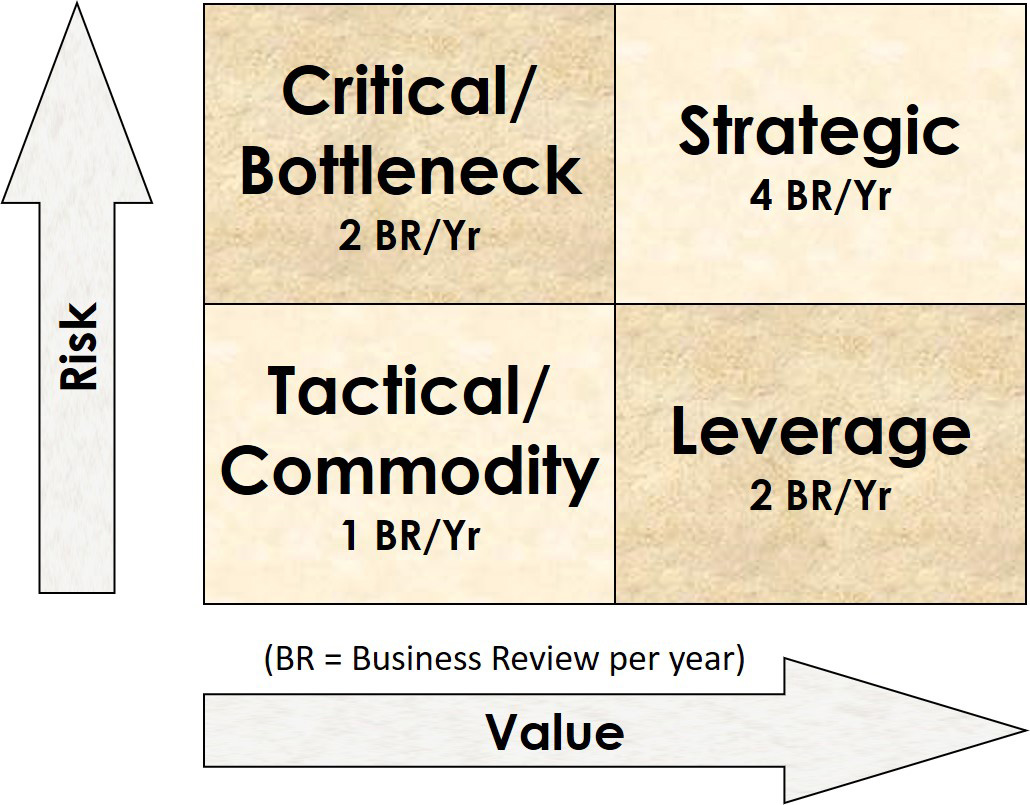

The way to evaluate suppliers and materials according to value and impact, or risk is to assign suppliers and their materials to one of four quadrants as shown. The quadrants help you prioritize where to invest time, attention and strategic importance based on value, impact, risk and relationship.

Commodity type generally means these suppliers are plentiful and materials you buy from this kind of supplier are easier to source, generally having lower risk of supply interruption and are not generally going to impact your products and services directly. Examples here might be retail store uniforms, laundry services, consumables that customers don’t see.

Leverage type suppliers are often more than one source, allowing some room for price negotiations, because the supplier knows you have choices. But unlike office supplies or uniforms, these may be more specialized and by that offer greater impact to your value. Example here might be soft drinks in the fast food retail store. Syrups that add lots of profit but generally not a lot of risk.

Bottleneck type or critical suppliers and their materials often are fewer options as far as sourcing, probably having more cost to procure and may be sole source materials with specific requirements that are critical to your processes and quality overall. Such materials and suppliers require significantly more focus and attention to assure no disruption and lowered risk to maintain supply continuity. Examples here might be fast food retail packaging. Very specific to just your products and needed on a regular basis but you are not the only customer of this supplier so interruptions can happen. Not a commodity, and therefore may have more risk, this kind of material and supplier needs more attention watching for early warnings of problems.

Strategic type suppliers offer the highest impact to your value, and also a lot more focus and frequency while also using collaboration to partner on key issues that help you and the supplier become more successful. Often this is not so much about price but about quality and high commitment to supply continuity. This supplier is also more likely to be involved in product development and managing key elements of supply fulfillment such as VMI, vendor managed inventory and lean initiatives that earn you both more profits.

If you are interested in learning more, check out our website for opportunities that fit your specific need.

Bob Forshay, SupplyChainPro2Know

info@supplychainPro2Know.com

www.supplychainPro2Know.com